The thermal properties of polymeric materials are fundamental to the fields of engineering and manufacturing. Understanding how these materials respond to heat is essential for designing products that perform optimally under various conditions. Polymers’ ability to manage temperature changes impacts their functionality and longevity significantly. As industries increasingly rely on polymers for various applications—from automotive components to consumer goods—grasping these thermal characteristics becomes paramount. This knowledge informs material selection and influences processing techniques, product design, and overall performance in real-world applications. When considering Vicat Softening Temperature vs Heat Distortion Temperature, two key parameters, VST and HDT, help evaluate a material’s behavior under heat, making them essential for material selection and performance analysis. Understanding the differences and applications of these temperatures allows engineers to make informed decisions that enhance the durability and reliability of their products.

Defining the Terms

Vicat Softening Temperature (VST)

The Vicat Softening Temperature (VST) refers to the specific temperature at which a material begins to soften when subjected to a defined load. This critical property is essential for understanding how materials will behave under heat and stress in various applications.

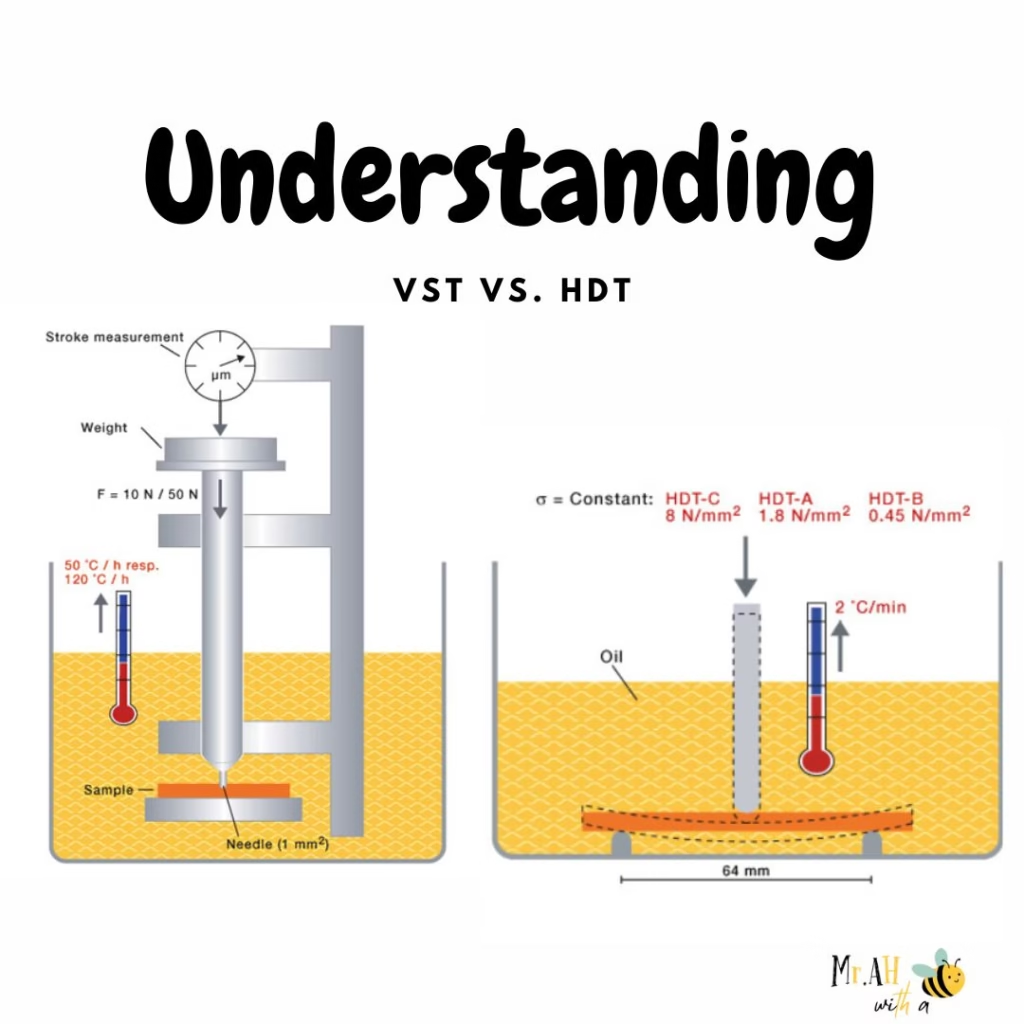

The Vicat test is employed to determine the VST. This process involves heating the material at a controlled rate while simultaneously applying a small, standardized load. As the temperature increases, a needle is used to penetrate the material. The VST is reached when the needle sinks to a predetermined depth, indicating that the material has softened sufficiently.

This measurement is crucial in plastics and polymers, where thermal performance impacts durability and functionality. Understanding VST helps engineers select materials that withstand environments without compromising performance.

Factors affecting VST

The Vicat softening temperature (VST) of polymeric materials is influenced by several key factors, including polymer composition, blending techniques, and chemical structure. Understanding these factors is crucial for optimizing the thermal properties of polymers for various applications.

Polymer Composition and Blending

- Blending with Other Polymers: The addition of polymers like PMMA to PVC significantly enhances the VST, achieving a maximum of 80.6 °C compared to 70.5 °C for unmodified PVC (El-Hakim et al., 2021).

- Polyethylene Blends: The combination of polyethylenes with varying densities can also improve VSP, as the density difference affects the thermal properties of the resulting composition.

Chemical Structure

- Substituent Effects: The presence and position of substituents in polystyrenes can elevate the softening point. For instance, larger non-polar substituents in the o-position increase the softening point more than those in the p-position (Barb, 1959).

Composite Structures

- Layered Composites: The design of composite materials with multiple thermoplastic layers can lead to improved VSP, enhancing their utility in applications requiring high thermal resistance (El-Hakim et al., 2021).

Heat Distortion Temperature (HDT)

The Heat Distortion Temperature or heat deflection temperature (HDT) is defined as the temperature at which a material experiences deformation when subjected to a specific load. This property is crucial for assessing how materials will perform under thermal stress in real-world applications.

To determine the HDT, the testing process adheres to the ASTM D648 standard. During this test, a constant load is applied to a sample material while the temperature is gradually increased. As the temperature rises, the material is monitored until it bends or deflects to a predetermined degree, indicating that it has reached its heat-deflection threshold.

Understanding the HDT is essential for engineers and manufacturers, especially when selecting materials for applications that involve exposure to heat or mechanical stress. In automotive, aerospace, and construction, knowing HDT ensures materials maintain integrity under stress. By evaluating this temperature, designers can make informed choices that enhance the reliability and safety of their products.

Factors affecting HDT

The heat deflection temperature (HDT) of polymeric materials is influenced by several key factors, including crystallinity, thermal history, and the presence of additives. Understanding these factors is crucial for optimizing the performance of polymers in high-temperature applications.

Crystallinity and Morphological Changes

- Increased crystallinity generally leads to higher HDT values. Using fatty bis-amides in poly(l-lactide) improved crystallization, achieving HDT near 120 °C (Rubinstein et al., 2022).

- In polypropylene, specific morphological changes at mold temperatures of 20–30 °C were linked to increased melting points and crystallinity, affecting HDT measurements (Wong, 2003).

Thermal History and Creep

- The thermal history of polymers plays a critical role in HDT. For polycarbonate, the contribution of creep to HDT values varies significantly, indicating that physical aging impacts HDT through structural relaxation rather than residual stress (Li & Mason, 2009).

- Amorphous polymers exhibit a sharp drop in modulus at the glass transition temperature, making HDT a predictable property, while semi-crystalline polymers show a plateau region, complicating HDT predictions (Takemori, 1979).

Additives and Fillers

- The addition of fillers can greatly influence HDT, particularly in semi-crystalline polymers, where they can enhance stiffness and thermal stability. However, in amorphous polymers, fillers have a negligible effect on HDT (Takemori, 1979).

Importance of Vicat softening temperature vs Heat distortion temperature

Thermal properties of polymeric materials like Vicat softening temperature and heat distortion temperature are critical in material selection across a broad range of industries:

Automotive and Aerospace

In the automotive and aerospace sectors, understanding thermal properties is vital to ensure that materials can endure the operational heat generated during use. Components must retain integrity and performance under extreme temperatures, like car engine parts or aircraft. Selecting materials with appropriate heat resistance helps enhance safety, efficiency, and longevity, ultimately contributing to the overall reliability of vehicles and aircraft.

Electronics

In the electronics industry, it is crucial to prevent deformation of materials in high-temperature environments. As electronic devices become more compact and powerful, they generate significant heat during operation. Materials used in these devices, such as circuit boards and enclosures, must possess excellent thermal stability to avoid warping or failure. Proper material selection ensures the longevity and performance of electronic components, safeguarding them from overheating and enhancing user safety.

Manufacturing

In manufacturing, knowledge of thermal properties helps optimize molding and processing conditions. For instance, when creating plastic parts, understanding the Vicat softening temperature, heat deflection temperature, and other thermal characteristics allows manufacturers to set appropriate temperatures and pressures during production. This optimization can lead to improved product quality, reduced waste, and increased efficiency in the manufacturing process. By selecting materials that align with specific thermal requirements, manufacturers can enhance productivity and ensure that the final products meet industry standards.

Key Differences Between Vicat softening temperature vs Heat distortion temperature

| Aspect | VST | HDT |

|---|---|---|

| Measurement Focus | Onset of softening | Onset of deformation |

| Testing Conditions | Needle penetration under a small load | Load applied until bending is observed |

| Material Implications | Reflects processability and surface stability | Indicates structural integrity under load |

Applications of Vicat softening temperature vs Heat distortion temperature

Vicat Softening Temperature

Plastic Molding

The Vicat Softening Temperature is a key metric in plastic molding, as it determines the upper-temperature limit at which materials can be effectively shaped and formed. Knowing the VST helps manufacturers choose processing temperatures that keep materials malleable for molding. This understanding is crucial for achieving precise dimensions and maintaining the desired mechanical properties of the finished product, ultimately enhancing production efficiency and product quality.

Thermal Stability

In addition to its role in molding, the Vicat Softening Temperature is a vital indicator of a material’s thermal stability. It assesses how well materials resist softening under elevated temperatures during manufacturing processes. Evaluating VST helps manufacturers understand material behavior under heat, crucial for high-temp applications. This knowledge can guide the selection of materials for products that must maintain their shape and performance in demanding environments, contributing to the durability and longevity of the final product.

Heat Distortion Temperature

Structural Applications

The Heat Distortion Temperature is a crucial factor in structural applications, as it ensures that components retain their shape and integrity when subjected to mechanical loads at elevated temperatures. Understanding the HDT allows engineers to design parts that can withstand the stresses of their operational environment without deforming. This is particularly important in industries such as construction, automotive, and aerospace, where structural integrity is paramount. By selecting materials with appropriate HDT values, manufacturers can enhance safety and reliability, ensuring that components perform as intended even under challenging conditions.

Design Decisions

The HDT also plays a significant role in guiding design decisions, particularly when it comes to material selection for heat-sensitive components. Understanding HDT helps engineers select materials for high-temp parts that maintain shape and performance. This consideration is vital to prevent failures that could arise from warping or melting, which can lead to costly repairs and safety hazards. Incorporating HDT in design helps engineers create innovative, resilient products that last longer.

Real-World Examples

Polycarbonate

Polycarbonate is renowned for its high Vicat Softening Temperature (VST) and Heat Distortion Temperature (HDT), making it an excellent choice for automotive components. It withstands high temperatures, maintaining structural integrity in critical applications like headlamp lenses. Additionally, polycarbonate offers exceptional impact resistance and clarity, further enhancing its suitability for automotive use. By selecting polycarbonate for these components, manufacturers can achieve a balance of durability, safety, and performance, contributing to the overall quality of the vehicle.

PVC (Polyvinyl Chloride)

While PVC has a lower VST compared to other materials, it remains adequate for non-structural applications such as pipes, fittings, and siding. Its thermal properties allow it to perform well in environments where it does not face significant mechanical stresses or high temperatures. PVC is lightweight, cost-effective, and resistant to corrosion, making it a popular choice for plumbing and construction applications. Though not for high temps, its versatility and easy installation make it a top choice for many projects.

Nylon

Nylon exhibits excellent Heat Distortion Temperature (HDT), which makes it particularly suitable for applications involving gears and bearings that are exposed to heat and mechanical stress. It maintains performance in demanding environments like automotive engines and machinery. Additionally, nylon offers good wear resistance and low friction properties, making it ideal for moving parts that require longevity and reliability. By incorporating nylon into their designs, manufacturers can enhance the durability and efficiency of their products, ensuring they perform well under a variety of operational stresses.

Conclusion

In summary, the thermal properties of polymeric materials, particularly the Vicat Softening Temperature (VST) vs Heat Distortion Temperature (HDT), are fundamental to engineering and manufacturing. These properties are critical for understanding how materials respond to heat, which directly influences product design and performance across various industries. As manufacturers rely on polymers for various applications, understanding thermal characteristics is essential.

By evaluating the VST and HDT, engineers can make informed material selections, ensuring that products not only meet the necessary performance criteria but also withstand the rigors of their intended environments. This knowledge ultimately enhances the safety, efficiency, and longevity of products, making it a vital consideration in the modern landscape of material science and engineering.

FAQs

- What is the main difference between VST and HDT?

VST measures softening, while HDT measures deformation under load. - Why are VST and HDT important?

They help assess material behavior in high-temperature applications. - Which industries rely on VST and HDT?

Automotive, aerospace, electronics, and manufacturing. - How is VST tested?

A needle is pressed into the material under heat until it penetrates a specified depth. - What is the standard for HDT testing?

ASTM D648, which measures deformation under heat and load. - Do all materials have both VST and HDT?

Not all; primarily thermoplastics and certain composites are tested. - What affects these properties?

Composition, additives, and processing conditions. - Can HDT predict material durability?

Yes, especially for components exposed to heat and stress. - Is VST higher for thermoplastics or thermosets?

Thermosets usually have a higher VST due to their cross-linked structure. - Are there tools to calculate these properties?

Yes, specialized testing machines for both VST and HDT are available.

If you like reading this, you may find these articles as well

Thanks for reading for more interesting articles visit our homepage.