The Allen wrench, also known as a hex key or hex wrench, is a small, L-shaped tool designed to drive bolts and screws with hexagonal sockets. Though it may seem like a simple tool, the Allen wrench is an essential component in a wide range of applications—from assembling furniture to working on bicycles, machinery, and even automobiles. Its popularity stems from its simplicity and versatility, making it indispensable in both professional and DIY settings.

This guide will provide a detailed overview of the Allen wrench, its types, uses, sizes, and tips for maintenance, helping you get the most out of this handy tool.

What is an Allen Wrench?

An Allen wrench is a small hand tool used to drive bolts and screws with hexagonal sockets, also known as Allen bolts. The name “Allen” comes from the Allen Manufacturing Company, which patented the design in the early 20th century. Hexagonal screws and bolts are preferred in many applications because they allow for a firm grip, reducing the risk of slippage.

Shape and Design

The classic Allen wrench has an L-shape, allowing the user to generate torque when driving screws or bolts. It typically has six equal-length sides, giving it a snug fit into hexagonal screw heads, as shown below.

Materials Used

Allen wrenches are commonly made from steel alloys such as chrome vanadium or stainless steel, which provide durability and resistance to wear and tear. Some may also have coatings, such as black oxide or chrome plating, to prevent rust.

Types of Allen Wrenches

Allen wrenches come in various shapes and sizes, each suited for different tasks. Below are the most common types:

L-Shaped Allen Wrenches

These are the standard type of Allen wrenches, easily found online or at local hardware stores. Shaped like an L, this Allen wrench can access tight spaces while offering control when necessary. One arm is longer than the other, allowing you to switch between torque and accessibility.

The shorter arm is used for tasks requiring more force, while the longer arm provides better reach in tight spaces. If you’re in the market for a set, this would be an ideal choice. Although many options are available, a 1.5-10mm L-size Allen wrench is perfect for a variety of needs.

T-Handle Allen Wrenches

The T-handle Allen wrench allows for quick and easy rotation, offering a long handle for added leverage during regular use. They are ideal for applications where repetitive use is required which makes it a most popular tools in bike mechanics and are commonly used in automotive or machinery maintenance, because they reduce hand fatigue.

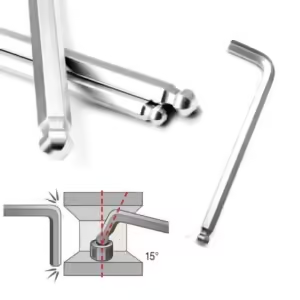

Ball-End Allen Wrenches

A ball-end is a straightforward tool designed for turning bolts and screws with hexagonal socket heads. This design allows the wrench to be used at an angle. Which makes it easier to reach screws in hard-to-access areas. It features ball-shaped molded heads with sharp edges. The ball end of the Allen wrench enables easy insertion into the receiving slot.

The ball-end wrenches are not ideal for heavy torque, however they are perfect for precision work where flexibility is more important than power. This design allows the user to access a 30-degree offset angle, making it quick to reach the desired position. It’s particularly useful for maneuvering into tight spaces that are difficult to access with standard L-shaped wrenches.

Torque Allen Wrenches

This type of Allen wrench is designed to apply a specific torque to fasteners like nuts, bolts, or lag screws. Torque wrenches with hex keys are used when precise torque is required. These wrenches have adjustable settings that allow the user to control the amount of force applied to a bolt or screw, making them essential for delicate tasks such as electronics assembly.

It functions similarly to a socket wrench, featuring a special internal mechanism. These tools are essential in situations where the tightness of screws and bolts is crucial. It is a vital addition to any workshop, particularly when handling sensitive components. However, this torque wrench should not be considered a replacement for hex wrenches.

Common Sizes and Measurements

Allen wrenches come in both metric and SAE (standard American English) sizes, and choosing the right one for your task is crucial to avoid stripping screws or damaging tools.

Metric Sizes

Metric Allen wrenches range from 1.5mm to 10mm, with common sizes including 3mm, 4mm, and 5mm. These are frequently used in bicycles, furniture assembly, and various European-manufactured products.

SAE Sizes

Imperial Allen wrenches, measured in inches, range from 1/16 inch to 3/8 inch. These are common in U.S.-made machinery and automotive applications. Common sizes include 3/32 inch, 1/8 inch, and 5/32 inch.

Choosing the Right Size

To ensure a snug fit, always match the size of the Allen wrench to the corresponding bolt or screw. If you’re unsure of the size, measure the diameter of the screw’s hex socket to find the appropriate tool.

How to Use an Allen Wrench

Using an Allen wrench correctly ensures that you can fasten or loosen screws without causing damage.

Step-by-Step Instructions:

- Insert the short end of the wrench into the hex socket for better torque.

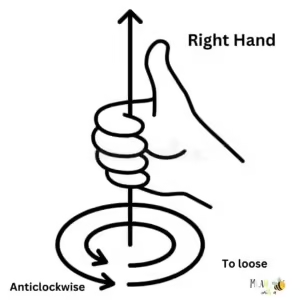

- Turn the wrench in the desired direction (clockwise to tighten, counterclockwise to loosen), as they say “Righty tighty, lefty loosey” or see the hand rule illustrated above.

- If more reach is needed, use the long end of the wrench.

- Apply steady pressure, but avoid using excessive force to prevent rounding off the hex socket.

Tips for Success

- Ensure that the wrench is fully seated in the screw head to avoid stripping the socket.

- Use the short end of the wrench when more torque is required, and the long end when you need more reach.

Common Mistakes to Avoid

- Using the wrong size Allen wrench can damage both the wrench and the screw.

- Over-tightening screws can strip the hex socket, making it difficult to remove the screw later.

Maintenance and Care

Proper care of your Allen wrenches will extend their lifespan and ensure optimal performance.

- Cleaning:

Wipe your wrenches with a clean cloth after each use to remove dirt and debris. For wrenches exposed to moisture, apply a light coating of oil to prevent rust. - Storage:

To keep your wrenches organized and in good condition, store them in a dedicated tool case or on a magnetic strip. This prevents loss and keeps them easily accessible.

Applications of Allen Wrenches

Many industries use Allen wrenches as versatile tools. Some of the most common applications include:

- Furniture Assembly

Many flat-pack furniture items, such as those from IKEA, come with screws that require an Allen wrench for assembly. The hexagonal design provides better torque, making it easier to assemble pieces securely. - Bicycles:

Bicycle maintenance often involves Allen wrenches for adjusting seat heights, handlebars, and brakes. The compact design of the tool makes it easy to carry for on-the-go repairs. - Machinery and Automotive Work:

In industrial settings, technicians commonly use Allen wrenches to maintain machinery, secure parts, and adjust components in engines or electrical systems.

Conclusion

Allen wrenches are simple yet versatile tools that play an important role in a wide range of applications. From assembling furniture to maintaining bicycles and machinery, these hexagonal keys are invaluable for anyone who enjoys DIY projects or professional work. By understanding the types, uses, and maintenance tips for Allen wrenches, you can maximize their functionality and extend their lifespan.

FAQs About Allen Wrenches

- What is the difference between an Allen wrench and a hex key?

There is no difference; they are two names for the same tool. - Can you use an Allen wrench for any hexagonal screw?

Yes, Allen wrenches are specifically designed for hexagonal socket screws. - Are Allen wrenches available in sets?

Yes, most retailers sell Allen wrenches in sets that include multiple sizes. - What’s the best way to measure an Allen wrench size?

Use a vernier caliper or ruler to measure the diameter of the hexagonal head. - Can Allen wrenches be used for high-torque applications?

Yes, but make sure to use the short end for more torque. - What should I do if an Allen screw gets stripped?

You may need to use an extractor tool or drill to remove a stripped screw. - Are there electric versions of Allen wrenches?

Yes, you can fit electric screwdrivers with hex bits for faster work. - How do I maintain my Allen wrenches?

Wipe them clean after each use and store them in a dry place. - What are the common uses of ball-end Allen wrenches?

They are best at driving screws that are hard to reach and require an angled approach. - What are some tips for using an Allen wrench more efficiently?

Use a ball-end Allen wrench for easier access to screws at awkward angles. Consider a T-handle Allen wrench for better leverage and grip. Pre-organize your screws and hardware before starting. - Is there a technique for turning the wrench faster?

Yes! Instead of twisting with your fingers, try using both hands: one to hold the wrench and the other to turn it for more torque.

Thank you for reading, for more interesting articles visit our homepage.